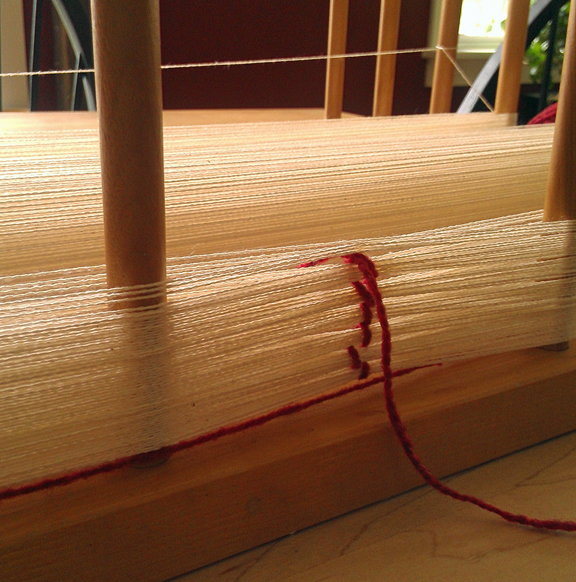

I went to the studio last night to thread the warp on one of the towels we are doing for our round robin. This warp is cotton in alternating colors – 4 threads blue, 4 threads white. Pam had wound the warp and beamed it (she did on all 11 looms, crazy woman). The threading, slaying and tie off was up to each student participating. She asked me to do this one.

I went to the studio last night to thread the warp on one of the towels we are doing for our round robin. This warp is cotton in alternating colors – 4 threads blue, 4 threads white. Pam had wound the warp and beamed it (she did on all 11 looms, crazy woman). The threading, slaying and tie off was up to each student participating. She asked me to do this one.

The warp was wound with the blue and white threads together so when I was threading I has to separate it into groups of 4 as I went along. I posted a pic to FB as I was doing it because the beginning seemed like a tangled mess to me and it was difficult for me to get a rhythm going that would carry me through.

Just as an FYI this is the sort of thing that makes me just a little crazy. I love order and symmetry and this seemed anything but. The threads would tangle together – blue and white as I threaded them through the heddles. I threaded them in groups of eight. When the blues were threaded the whites were tangled but once I finished the whites it seemed to straighten out. For a person with an OCD in order and symmetry this was pretty stressful.

It gets better. Being the novice that I am I counted the heddles on the first shaft to make sure there were enough before I started – I figured I was good to go. You guessed it – I was short on two shafts at the end. DAMN IT! I had to move heddles from one side of the harness to the other which was a struggle (that, my friends, is a wild understatement).

I had been looking forward to a quiet evening meditation with fiber. I got a hot, frustrating 3 hours.

There are lessons learned here. The most obvious to me is count your heddles – all of them, don’t assume anything. The next is that I can fix my mistakes for the most part. The most important one for me is learning to work through that OCD. Yeah, yeah, it made me short of breath with an extreme headache but once it was done I relaxed and thought “that wasn’t THAT bad”.

Years ago, in my quilting days, I had a lot of trouble letting go of control of my projects. The colors had to be just so, set in the right spots, the seams perfect, the points exact. I met a woman whose work I greatly admired. I worked with her on the CT Quilt Search Project for over 3 years where I saw scrap quilts that were stunning. I couldn’t figure out how they decided what went where to have these textiles of scraps come together with such beauty. We talked about it at one point and she said “Put all of your light pieces in one bag and your darks in another – as you’re sewing them together just pick random ones alternating from one bag to another”. That was way, way out of my comfort zone. I had no control but I forced myself to do it.

I ended up with a beautiful top, exactly what I was looking for made in probably half of the time because I forced myself to let go. I need to remember those lessons every time I do something that I’m frantically trying to maintain control of – you just have to let it go.

This week I decided to tackle the False Satin Blocks in 10/2 mercerized cotton. I chose a buttery yellow for the weft. I sat down at this loom last week and simply could not do this. I was over thinking to the point where I just had to walk away. I didn’t understand what the selvages were doing, the sheds weren’t opening the way they were supposed to, ugh! (Of course if I had just waited and asked a question or two that might have helped). I spent the entire week fretting about this whole set up. 8 shafts intimidate me, I’m not sure why. I think it was just out of my comfort zone right then. I was looking for meditation last week, this week I was up for the challenge.

This week I decided to tackle the False Satin Blocks in 10/2 mercerized cotton. I chose a buttery yellow for the weft. I sat down at this loom last week and simply could not do this. I was over thinking to the point where I just had to walk away. I didn’t understand what the selvages were doing, the sheds weren’t opening the way they were supposed to, ugh! (Of course if I had just waited and asked a question or two that might have helped). I spent the entire week fretting about this whole set up. 8 shafts intimidate me, I’m not sure why. I think it was just out of my comfort zone right then. I was looking for meditation last week, this week I was up for the challenge. Fred loves the studio. He is always there, waiting for a pat or cuddle (or food). He helped Pam read her measurements – we all know tempting any owner reading a paper of any kind is. I think he was just in tune to her frustration and was working on a little comic relief.

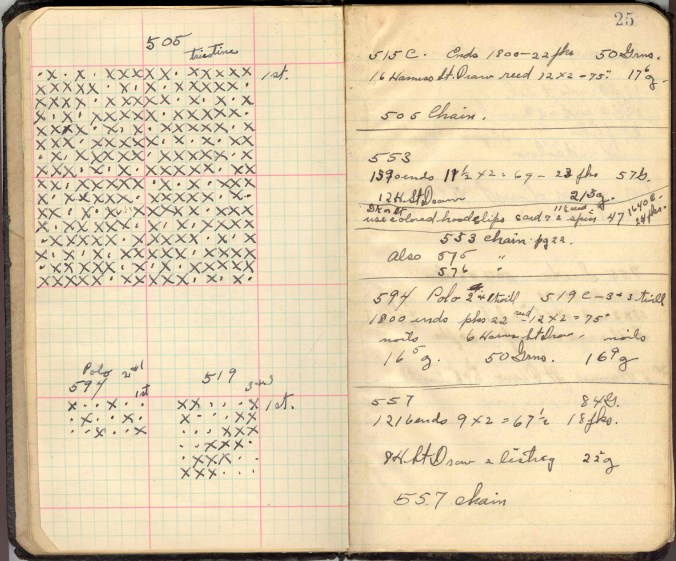

Fred loves the studio. He is always there, waiting for a pat or cuddle (or food). He helped Pam read her measurements – we all know tempting any owner reading a paper of any kind is. I think he was just in tune to her frustration and was working on a little comic relief.