Most of my family on both my mother’s and father’s sides immigrated to the United States in the late 1800’s, the majority of them went to work in woolen mills in various parts of New England. This is fairly typical for immigrants of that era. Their skills were learned on the job and they worked their way into different jobs in a particular type of manufacturing.

My father’s father, Elmer, worked in woolen mills his entire life. I can’t say for sure what all of his jobs entailed but he is listed in the 1930 Census as a Loom Fixer. He was a brilliant man and could fix anything, including machining any parts that he needed.

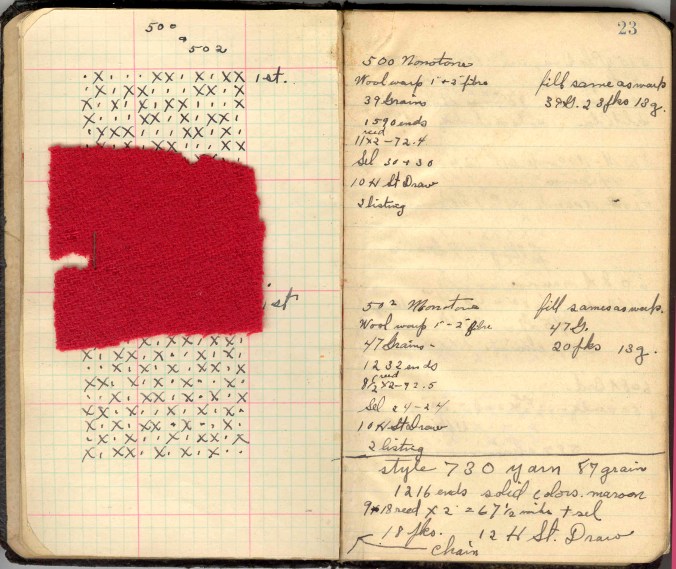

He left behind a number of books where he kept track of all sorts of things including loom set ups. I had never woven a thing so when I looked at this particular book it didn’t make any sense other than to know that they were drafts and swatches of fabric that he had woven. That’s pretty cool in itself.

He had his own woolen mill in the late 50’s and early 60’s and I’m assuming these were some of the drafts for what he was weaving at the time.

He had his own woolen mill in the late 50’s and early 60’s and I’m assuming these were some of the drafts for what he was weaving at the time.

Not ever having woven a thing I had no idea what he was talking about but felt like if I learned then I could be privy to his secret language, sort of get inside of his head.

Not ever having woven a thing I had no idea what he was talking about but felt like if I learned then I could be privy to his secret language, sort of get inside of his head.

A friend was moving last summer and posted on her Facebook page that she needed to get rid of her Harrisville loom and was anyone interested – I jumped on it. When I did I was thinking about this book and my family heritage with weaving. I googled weaving instructors for that particular loom and found Pam in Brimfield. I brought the book into class the second week to find out if I would be able to read it at some point. The mechanical looms are very different from the hand looms but what I’ve found is they are all the same really. She assured me that I would be able to read his drafts but would also be able to weave them

A friend was moving last summer and posted on her Facebook page that she needed to get rid of her Harrisville loom and was anyone interested – I jumped on it. When I did I was thinking about this book and my family heritage with weaving. I googled weaving instructors for that particular loom and found Pam in Brimfield. I brought the book into class the second week to find out if I would be able to read it at some point. The mechanical looms are very different from the hand looms but what I’ve found is they are all the same really. She assured me that I would be able to read his drafts but would also be able to weave them

I look at this book in a totally different way now. I understand what he was saying and doing and it’s truly amazing. He would write the drafts, set up the looms and then attach a swatch of what he had created in his mind. Wow.

In the past year of weaving class I have learned the mechanics of dressing a loom and weaving structure (the basics). I have learned that my brain works in a way where I can see from a draft what a weaving structure will look like. I’ve learned that I inherited the ability to do this and understand it. Now I can spend some time actually weaving some of the drafts that my Pampi wrote. How cool it that?